Hydraulic Press Brake

Sheet Metal Vacuum Lifting

Air compressor

Electronic Stabilizer

Smoke Filter

Raycus Laser Source

Max Laser Source

IPG Laser Source

Water Chiller TEYU

Cypenest(Cypcut) Software

Vacuum Pump Becker

Dust collector

Mist cooling System

Auto lubricating system

Infrared protection

CCD

Oscillating Knife

Push-Down roller-SHOP

Material Pop-Up Pins

Vacuum Cups Suction Pods

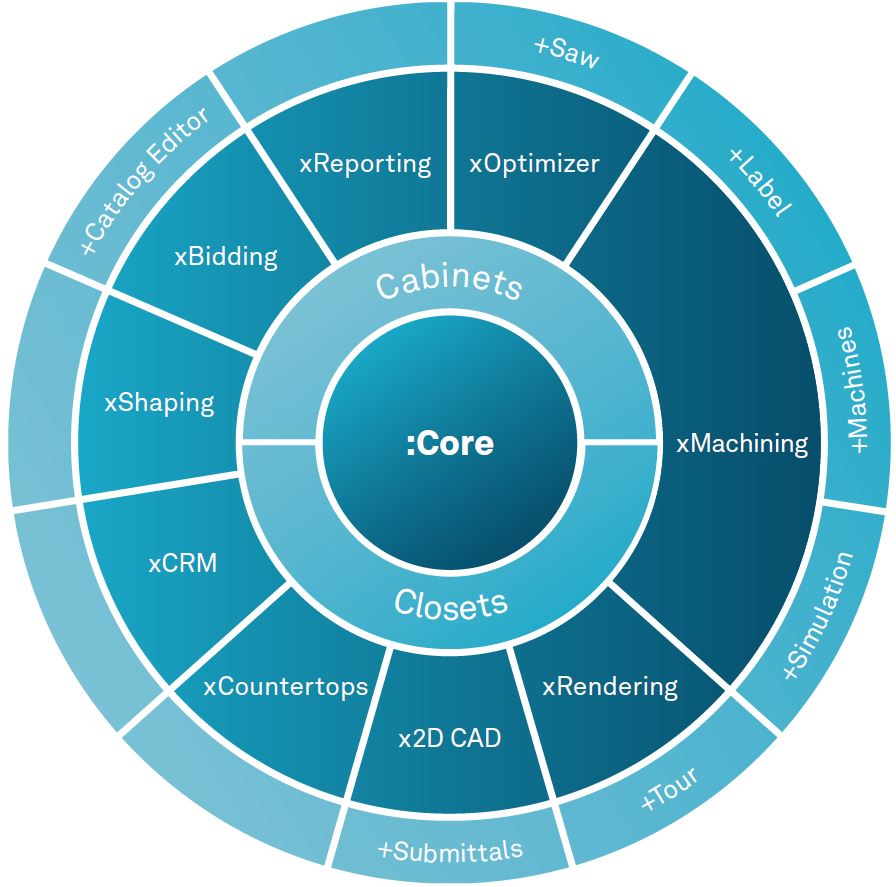

Cabinet version

Aspire Software

TYPEEDIT V13 Software